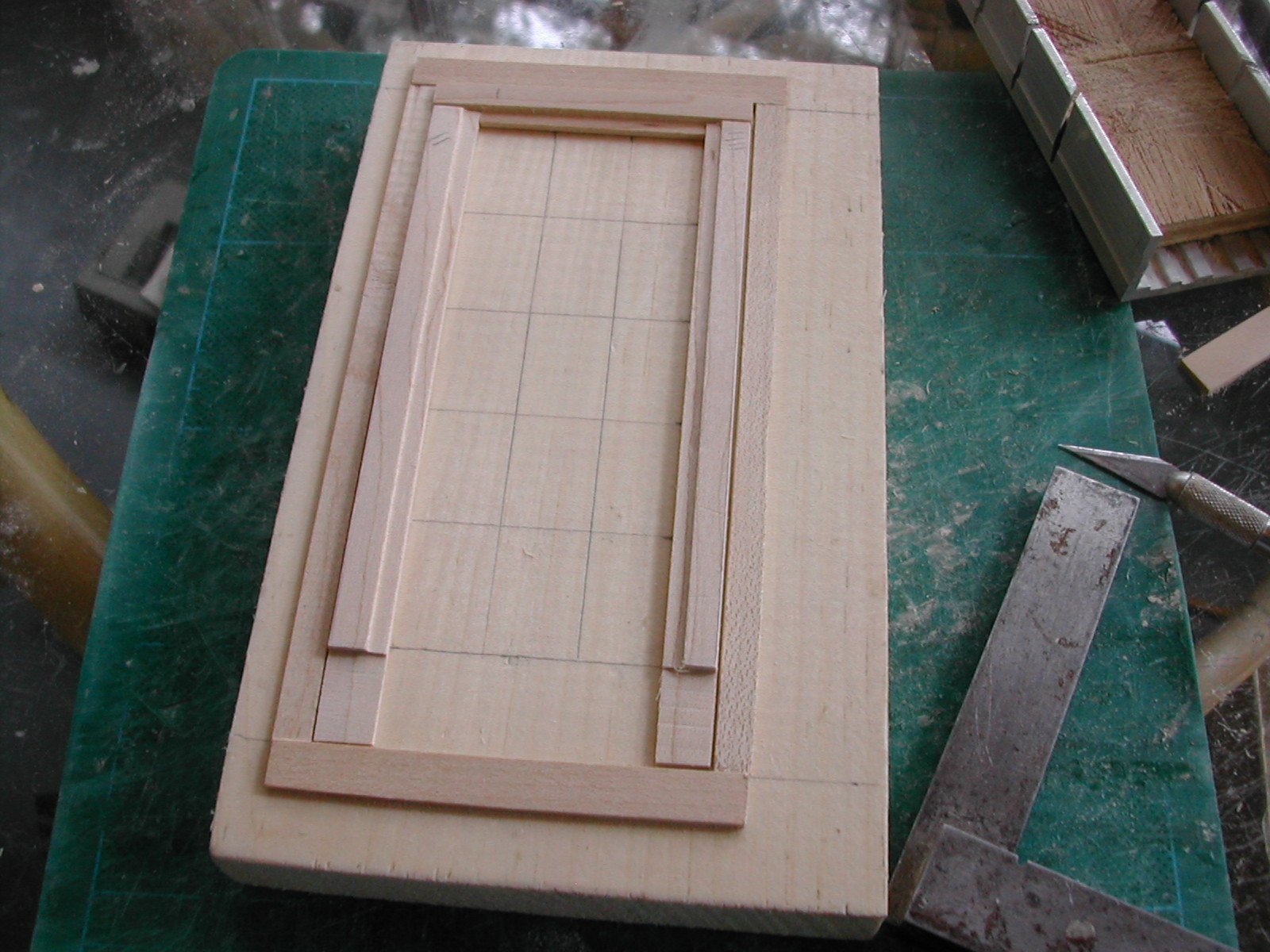

The first

step was to make the frame for the glass windows. Each door has two

frames.

The inside frame is made from 1/16" maple sheets. The outside

frame is made from 1/8" maple sheets. The outside frame is shown on the

photograph to the right. Three sides have been placed in the jig. Note

that the frame has a 1/16" recess for the window which was cut from a

plastic CD jewel case. The forth side has not jet been placed in

position. Note carefully how the corners are lapped to provide a larger

gluing surface. Note also that the locations of the mullions are

marked in pencil on the jig.

|

|

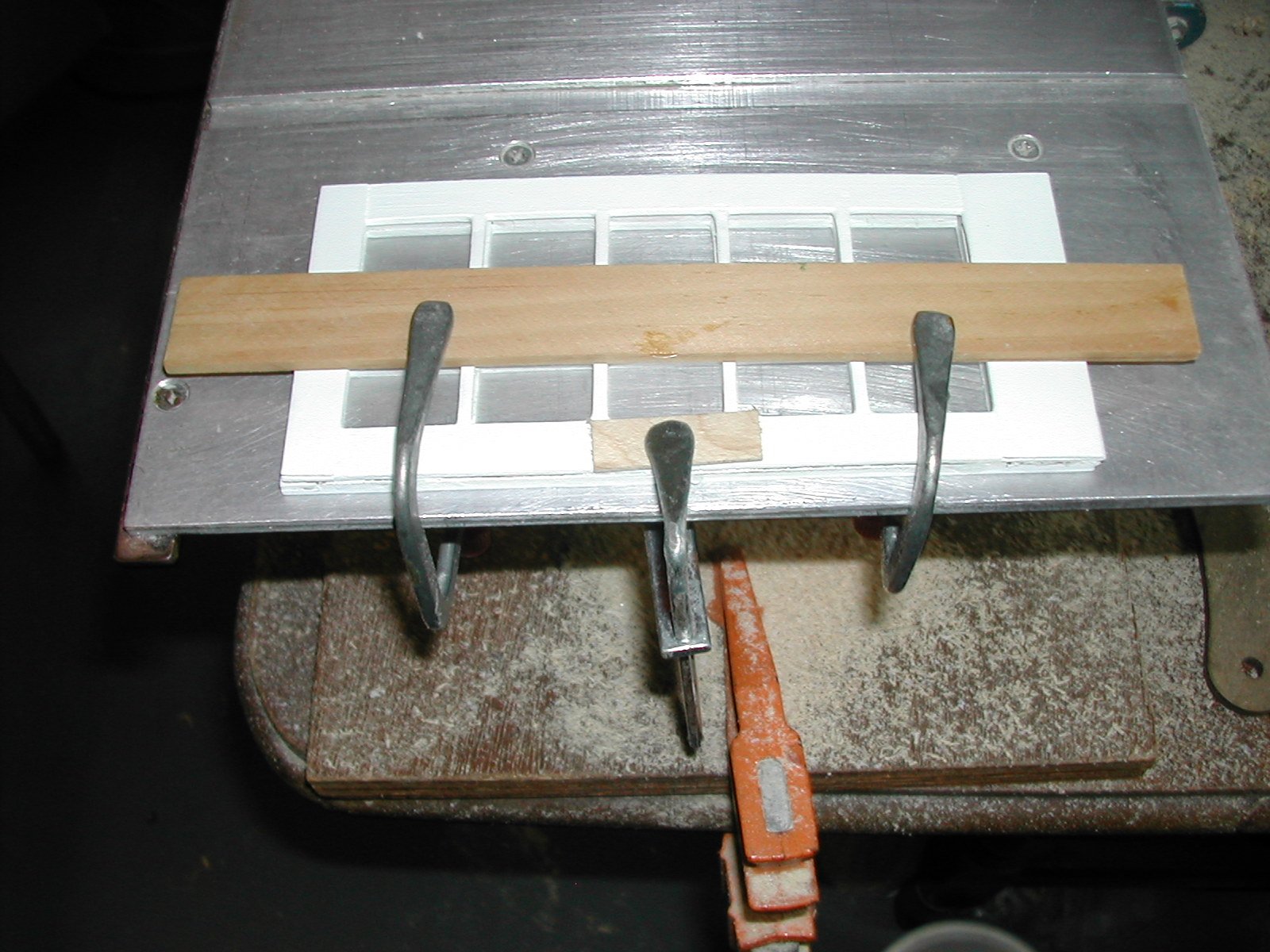

The forth

side, shown in the photograph to the right, is mounted in the milling

machine clamp. It is now ready for milling the lapped corner. The other

end

has already been milled and ready for putting into position. The

mullions are made in the same manner as those for the windows. The

frame, after sanding and gluing with Elmer's Carpenter's wood glue, is

then

ready for painting.

|

|

Here Eve is

painting the two sides of the door. Two coats of white primer were

applied and then two finishing coats of high gloss indoor paint.

Everything was sanded in-between each coat.

|

|

This

photograph shows the two sides of the door waiting for the paint to

dry. It was important to paint both sides of each panel because

the width of the plastic "glass" was deep enough so that you could

notice if the back of each side was actually painted white. The first

time we assembled a window having painted only one side, it became

immediately obvious that both sides needed to be painted.

|

|

After the

paint has dried, the door is ready to be assembled. Shown in this

photograph are the two sides of the door and the plastic CD jewel case

cut

and sanded lying diagonally across the lower panel.

|

|

These parts

are then glued together with five minute epoxy. In this photograph the

unit is clamped together waiting for the epoxy to completely set

(approximately

one hour).

|

|

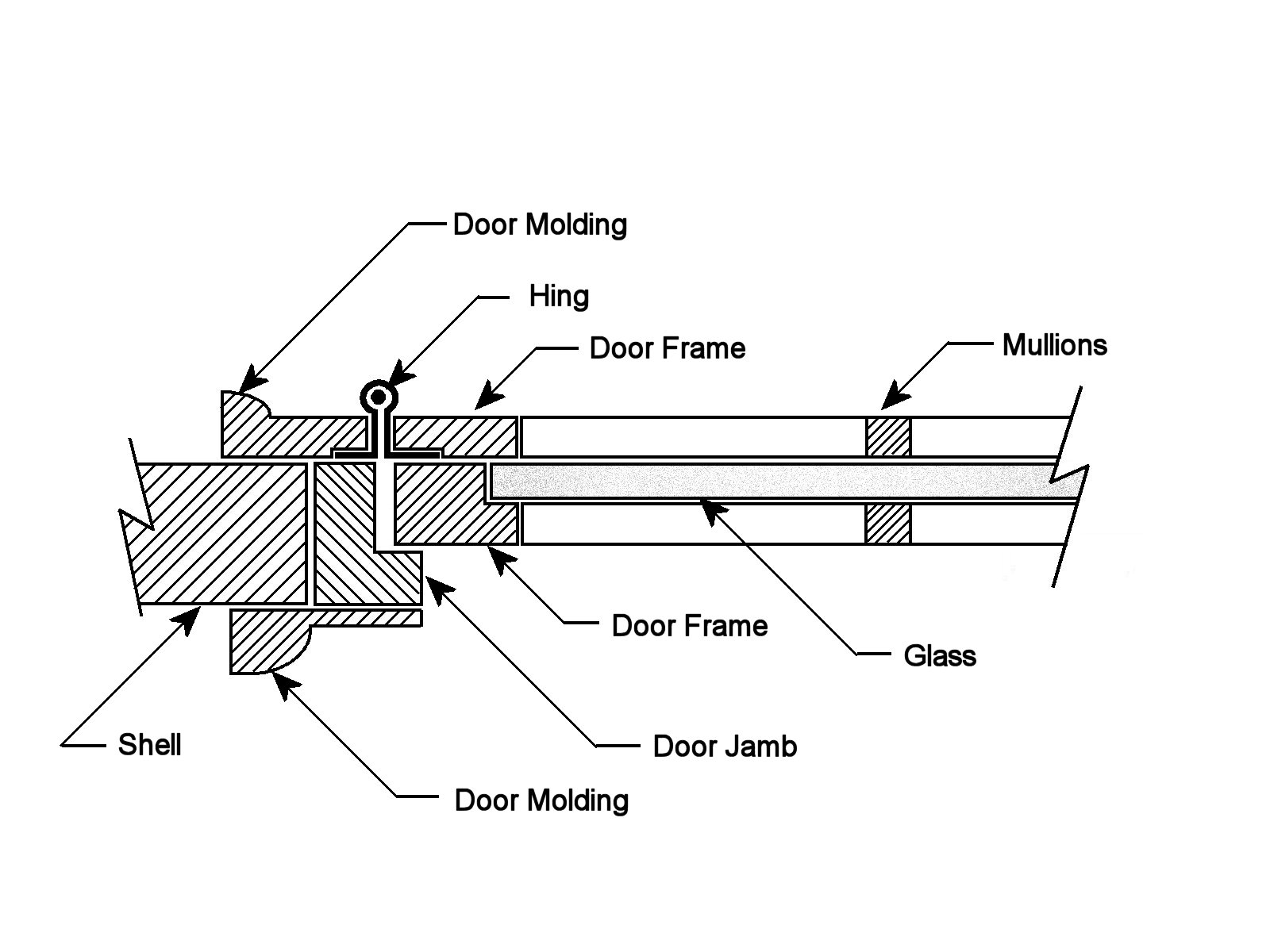

The sketch at

the right (not to scale) shows a crossection of the door, door jamb and

shell illustrating how the door hinges are mounted. These parts are

glued together with five minute epoxy.

|

|

Here is the interior of the dining

room panel that opens to allow access. The door is flanked by two

windows. As we do not actually use this door in the full size house, we

treat the entire wall as windows using a deep valance across all three

units (which serves to hide the fact that the middle door is much

lower than

the window frames) and floor length curtains along the entire wall to

create a wider illusion.

|

|

This is the exterior of the back

door in the kitchen. Note the piano hinges for the kitchen opening

panel and the one further to the right that opens the panel to the

dining room.

|

|