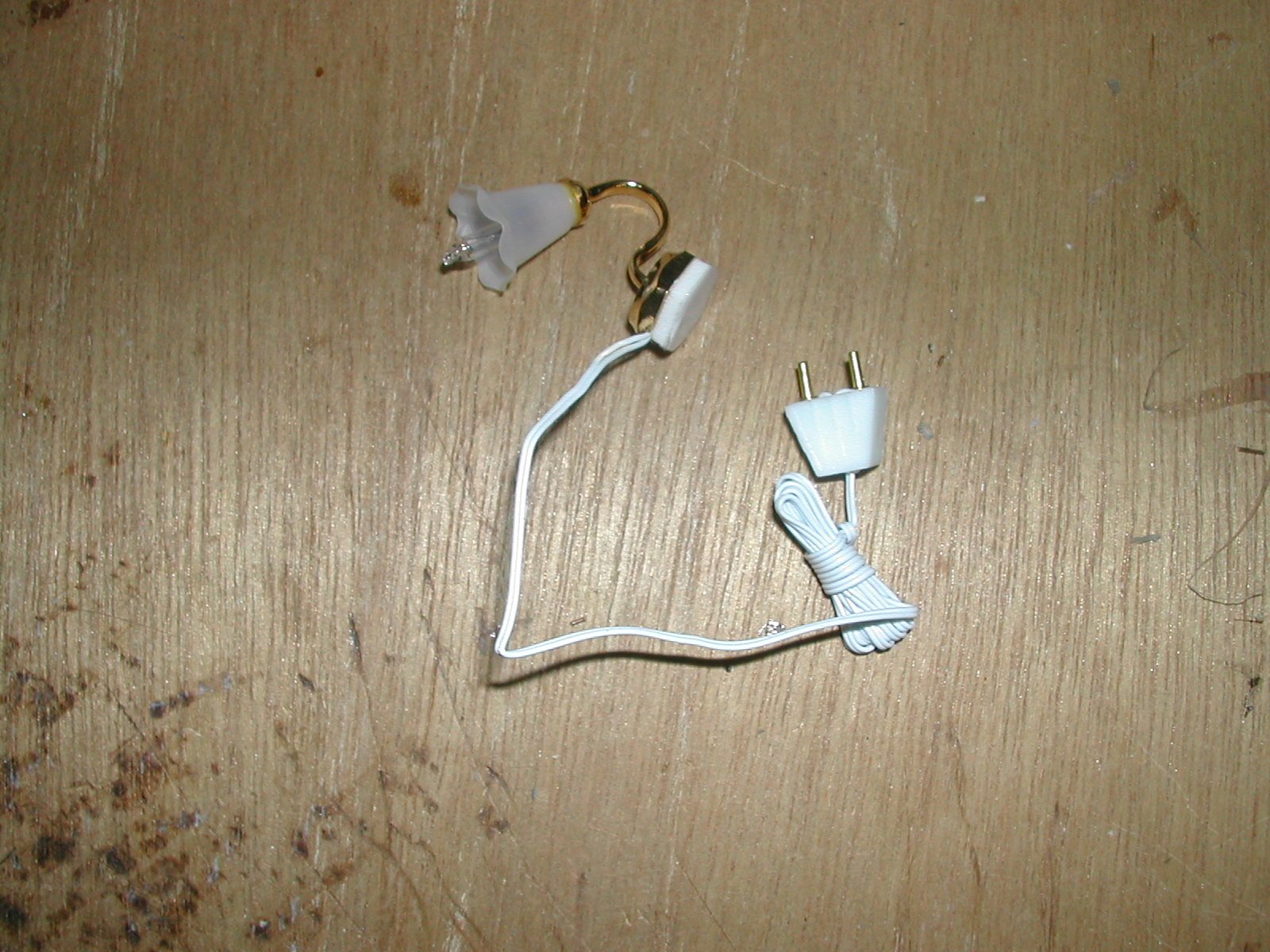

The type of

sconce lights that can be bought today is shown in

the photograph to the right. Note that the plug is very large and

greatly out

of

scale. You will also see that it requires a wire hanging down a wall.

To avoid this, the first step

was to cut off the existing wires leaving only about an inch. In

addition, the

backing was also removed. This left sufficient space in the base of

the sconce to rewire it with a miniature plug.

|

|

A new base

was cut from a Chap Stick Lip Balm case retaining just the bottom

section that turns to advance the stick upwards through the tube.

The plug wires are made from 22 gage solid copper wire which just

fits firmly into the existing wall and ceiling electrical outlets.

The new base and the copper wires for the new plug, which have not yet

been

assembled, are shown on the photograph on the right.

|

|

Next the

copper wires are soldered on to the old wires as shown on the right.

Since the wires used in these lights are 22+ gage and consist of

multiple strands, the insulation can not be stripped in the normal

manner without damaging the fine wires. Instead the insulation was

removed by heating and melting it with a soldering iron.

|

|

The next step

is to insulate the exposed soldered connection with liquid electrical

tape. Small holes are then drilled in the new base to match the spacing

on

the plug-in electrical outlets. The wires are then pressed into the new

base and held in place with five minute epoxy.

|

|

The final

fully assembled sconce unit is shown in the photograph on the right.

The

epoxy not only holds the wires in place and insulates them, but

also bonds the plastic base to the old base of the sconce.

|

|

This

photograph shows the sconces mounted on the wall in the hall opposite

the front door. If a bulb ever burns out it can now be easily replaced

by simply plugging in a new sconce light.

|

|

This

photograph shows the partially rewired chandelier which hangs in the

dinning room. As before, the plastic base was made from the cap of a

lip balm

dispenser. The 22 gage solid copper wire has been soldered in place and

the exposed wire has been insulated with the liquid electrical tape.

|

|

This

photograph shows some of the many table lamps and hanging ceiling

fixtures that needed to be rewired. The hanging fixtures were designed

to be plugged into the ceiling sockets. This allows for the changing of

fixtures and of light bulbs as they get worn out or malfunction.

Note the size of the new plugs attached to the lamps compared with the

ones sitting on the cutting board. The original plugs were wildly out

of scale. They would have measured five inches in width if they

had been

scaled up for a full size house. They were one of the oddities we

kept discovering in dollhouse supplies offered commercially and the

reason we had to replace, modify or build so many things that went into

this project.

|

|

A slightly

different view of the same lamps is shown on the right where the bases

can be examined and the unfortunate size of the original plugs

better observed.

|

|