A number of

bench tools were used to create the miniature. Among them were

an ACE Hardware 16" variable speed scroll saw, shown on the right. This

scroll saw was not made for making small model parts and had to be

modified. The slot where the saw blade passes through the table was

much too large and small parts could easily fall through. Therefore, a

flat board with a very fine slot was clamped to the table of the saw,

as

shown.

|

|

A second

bench tool, a Dremel Model 1731 belt/disc sander, proved an

invaluable help. This model can be fitted with varying grades of sand

paper depending on the need. It was used primarily to

shape small parts to the exact tolerances needed. It

was also used to shape some of the molding to give it an ogee

crossection.

|

|

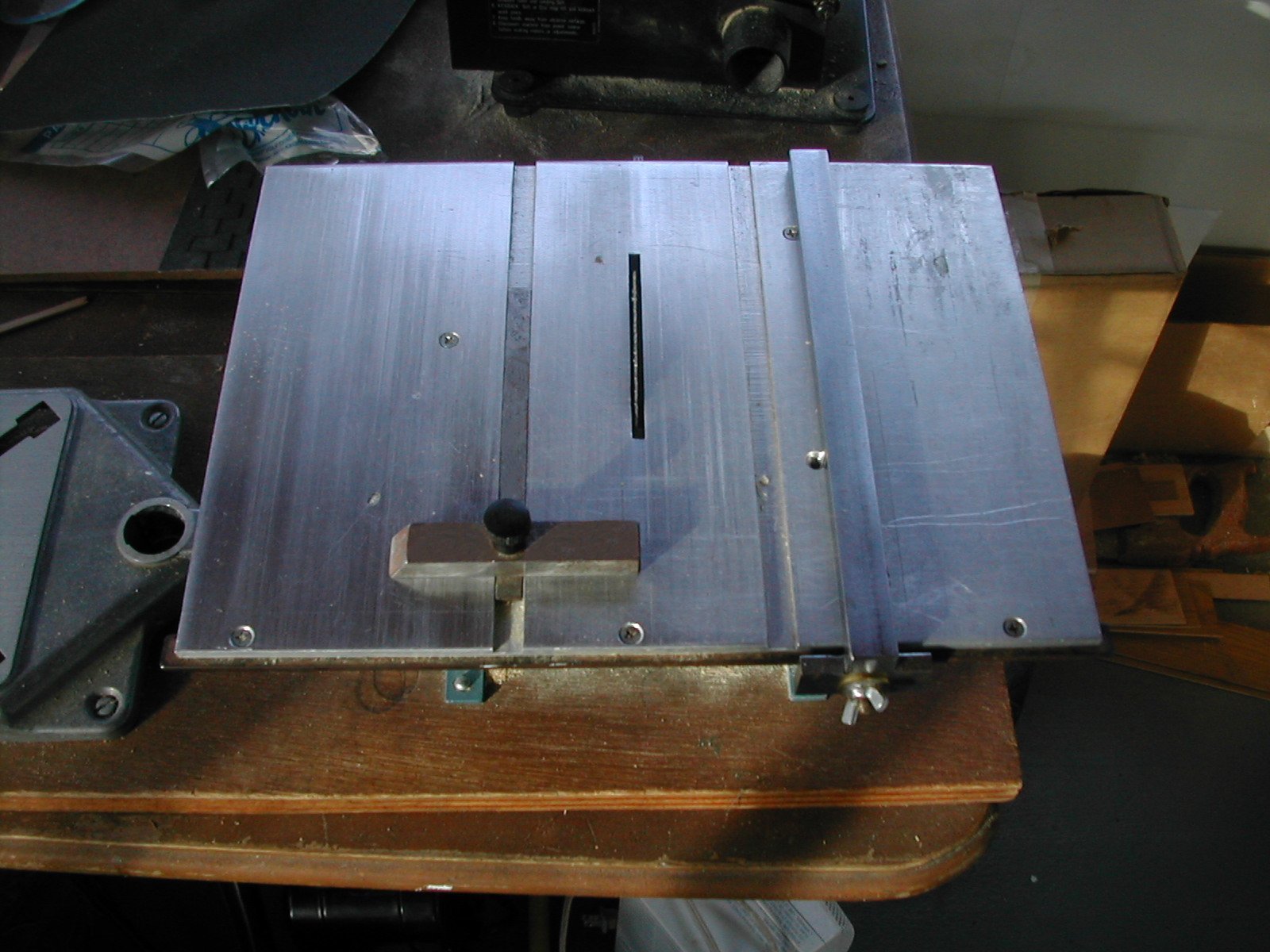

A third

indispensable tool was a Jarmac table saw, seen to the right.

Since I

would be cutting hard wood like maple, I kept rotating three blades; a

replacement blade and a blade that would be always be in a machine shop

for sharpening and one being used. A problem soon developed with this

model table saw.

Since the fence was frequently moved, the screw that tightened the

fence soon wore out. This was replaced with a steel machine screw

welded to the back plate and tightened with a wing nut.

|

|

A juri-rigged

milling machine was constructed for milling the numerous shapes of

molding and other parts. The Jarmac table saw was bolted to a plank of

wood

and used as the platform or flat table. A Dremmel Moto-Tool drill press

model 212, type II, was also bolted to the plank of wood in an

appropriate position and used to hold a Dremmel MultiPro variable speed

driver Model 395, type 5. The depth gage was removed and replaced with

steel bolts held by steel nuts. The nuts were adjusted to fix the

correct

height as seen in the photograph to the right.

|

|

In a

different view, shown in this photograph, you can see a

wooden movable platform with a clamp. The wood to be milled is clamped

to this platform and slid along the Jarmac fence which is used as a

guide to insure a straight cut.

|

|

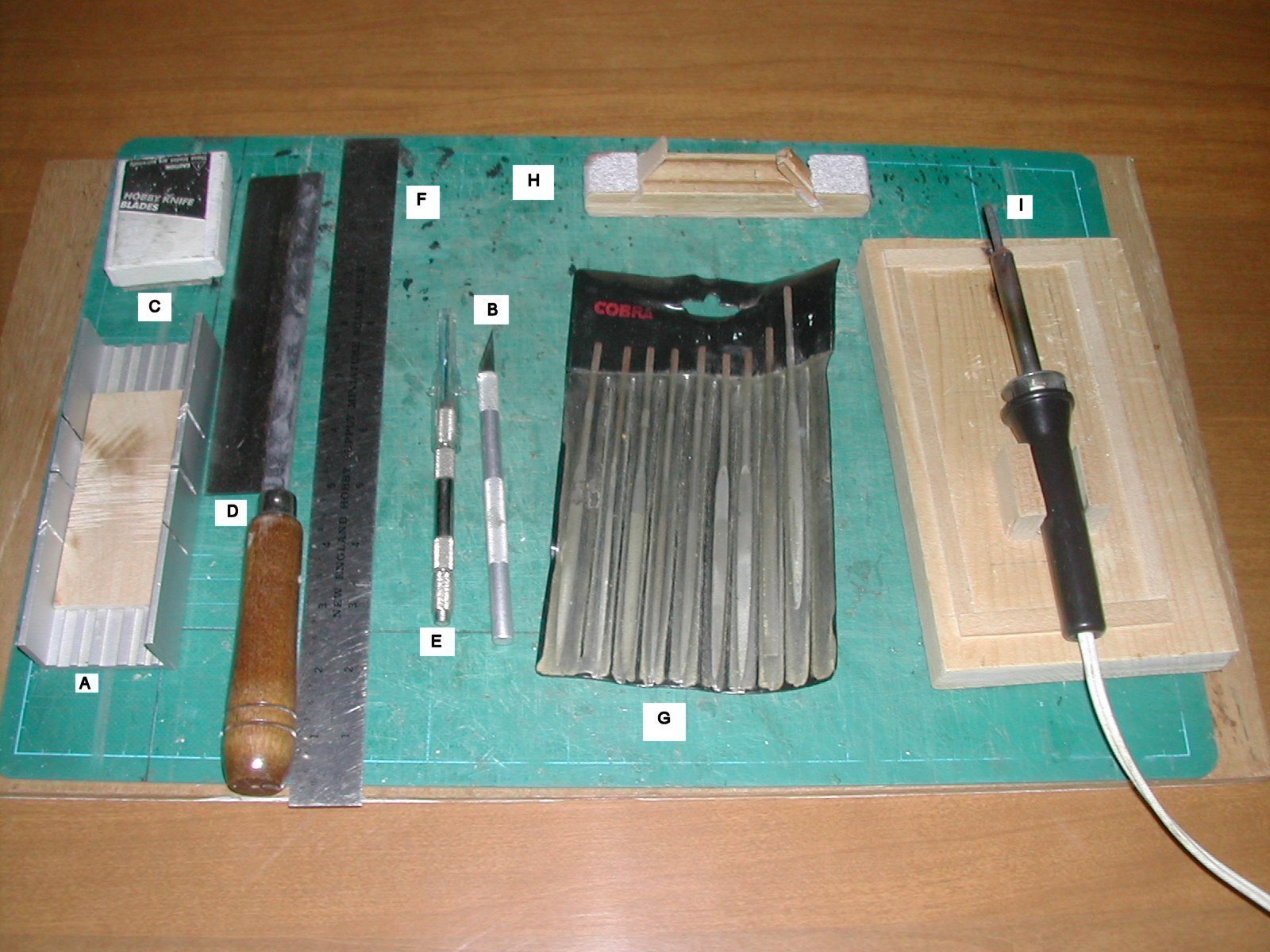

Some of the

small hand tools used in the construction of the miniature are shown in

the photograph to the right. These tools include an X-acto set

including a miter box "A", a small blade cutting knife "B" and a box of

blades "C". A block of wood is placed in the miter box to protect the

saw blade. The X-acto saw, which came with the set, was useless for

hard wood and replaced with the saw "D". Also used was a small

hand drill set "E", a 12" scale "F", a set of files "G", a sanding

block "H", and a soldering iron "I". These tools are shown on a "self

healing" rubber

cutting pad which was indispensable.

|

|

Additional

small tools are shown in the photograph on the right. These

include a set of clamps "A" of which only a few are shown, a large

number of Dremmel cutting bits used for milling "B" and circular saw

blades used for cutting slots for the tongue and groove construction of

the interior doors and Indian shutters. A makeshift hand disc sander

"D"

was constructed by gluing a rubber disc to a stone cutting tool. Small

sanding discs "E" were then fastened to the rubber disc. The

whole unit could then be used as a hand held disc sander. It was very

useful for sanding small parts down to the exact tolerances

required for miniatures. Finally we have a square "F".

|

|

The adhesives

used in the construction of the miniature are shown in the photograph

to the right. When gluing clean wood to clean wood such as the floor

boards, ordinary Elmer's carpenter's glue was used. A small syringe was

used for applying the adhesive. Elmer's Wood filler was used for touch

up. When gluing dissimilar parts together such as metal hinges to wood,

quick setting 5 minute clear epoxy was used. Both of these adhesives

required clamping of parts until the glue had set. Household "Goop" was

used for mounting the floor and crown moldings. This adhesive is tacky

enough so that it needs no clamping until it sets. In some cases Duco

cement was used, for example attaching the frames on the paintings.

This is a

quick setting glue and can be held in place with your fingers until it

sets.

Ordinary glue stick paste was used for mounting the wallpaper. Although

not an adhesive, shown here is Star-brite liquid electrical tape used

for insulating the electrical wires. This product is used extensively

in boat building.

|

|

The sandpaper

used ranged in grade from 120 grit up to 400 grit. All wood surfaces

prior to painting were sanded with at least 120 grit paper. Between

applying coats of paint, finer grades of sandpaper was used to get a

very fine finish. A sanding block is shown as well as a sanding stick

for very small surfaces. One can mount a sanding belt of various grades

on the spring mounted stick.

|

|